Application example: Forming of steel tubes with different coatings can be realized in the 4 station process lineup of this unit. Different highly tempered mold groups covering a large variety of products and ensure a damage free forming of the final article. In addition, a material bunker enables a max. 6h production without any operator […]

For many of our customers, we are not only a competent contact for special solutions in the areas of automation, assembly systems and devices, but often also a valuable project partner for their own machine concepts. Shown here is an example of a large-format machine frame. With our internal manufacturing capabilities, we cover various areas […]

Under the motto of refreshing and expanding knowledge, we completed two training days as a team at our technical center robot cell over the last few days. New functions and program sequences were programmed and tested live. Thanks also to our training partner for 2 intensive days. More questions info@noma-gmbh.de

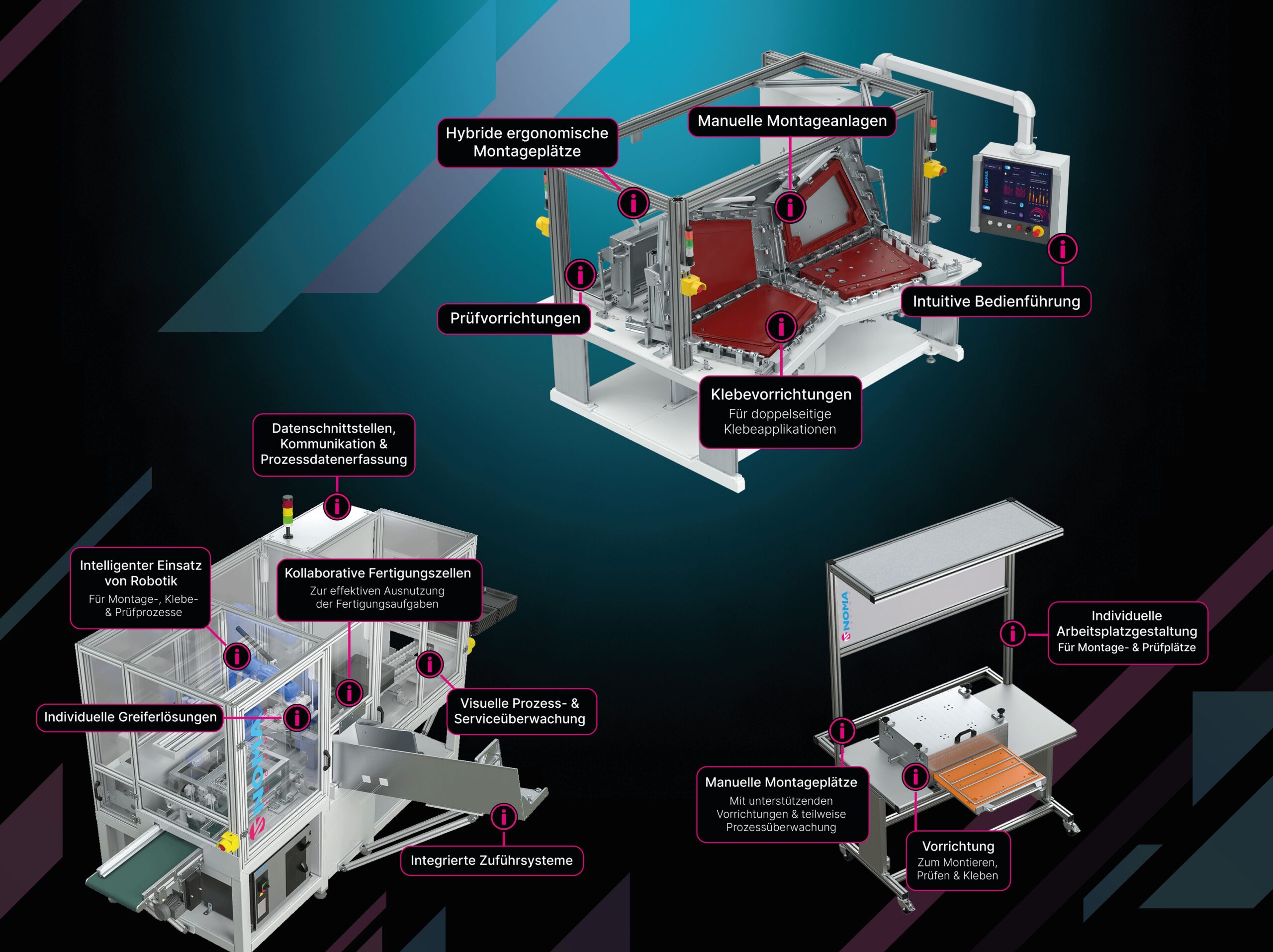

If maximum precision and optimal efficiency are required when applying double-sided adhesive tapes in small batch sizes, Noma Technik provides a proven guidance concept that enables precise positioning in ranges of +/-0.2mm. Link-guided in (almost) any geometry possible because the guide elements can be designed modularly. Double-sided adhesive tapes can be applied quickly and precisely […]

After the components have been formed, they must be separated in a further process without the additional intervention of another employee. The frame opening system developed for this purpose is a powerful and compact solution as a self-sufficient unit to the already established processes. Questions: info@noma-gmbh.de Application example: