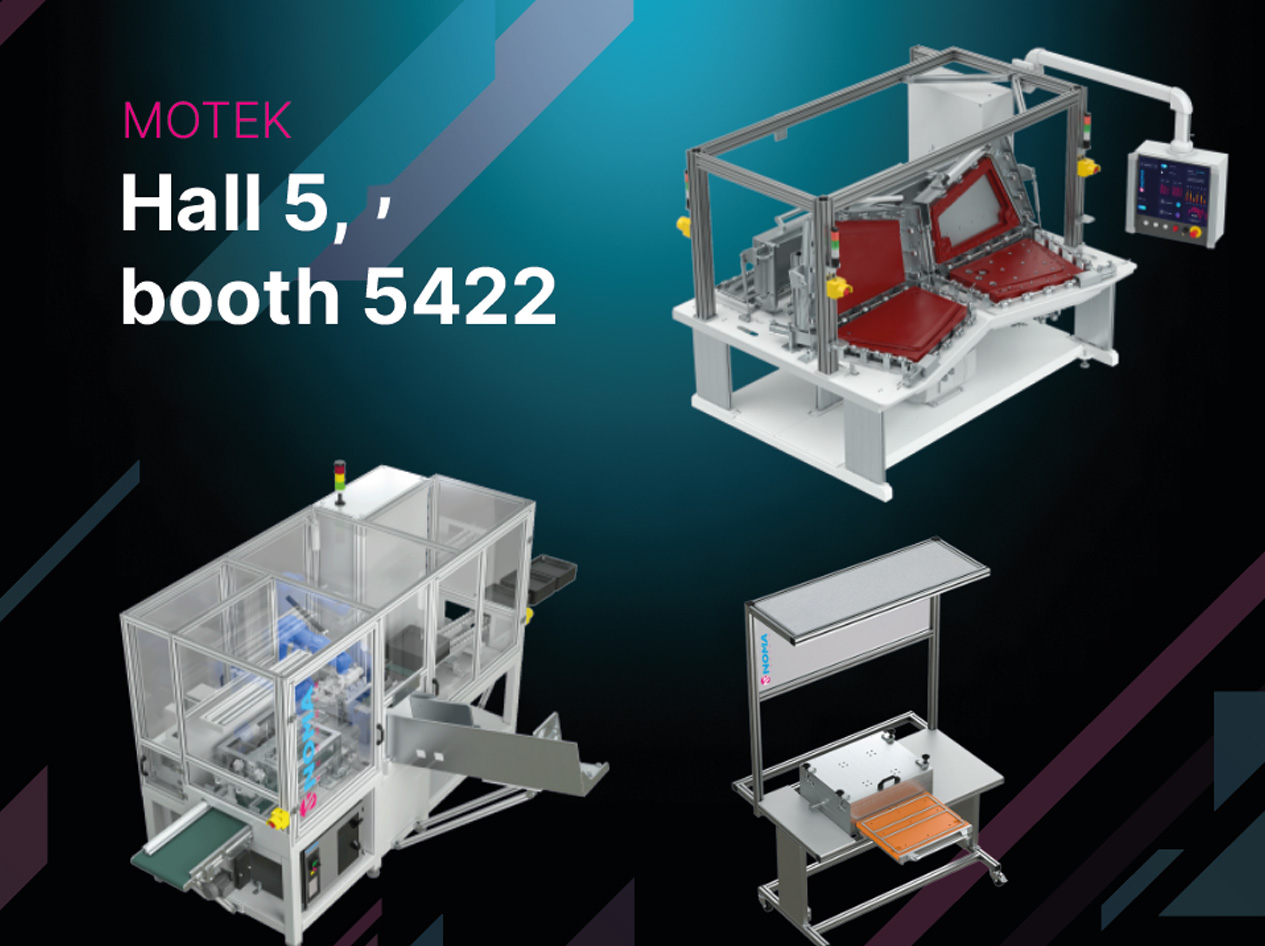

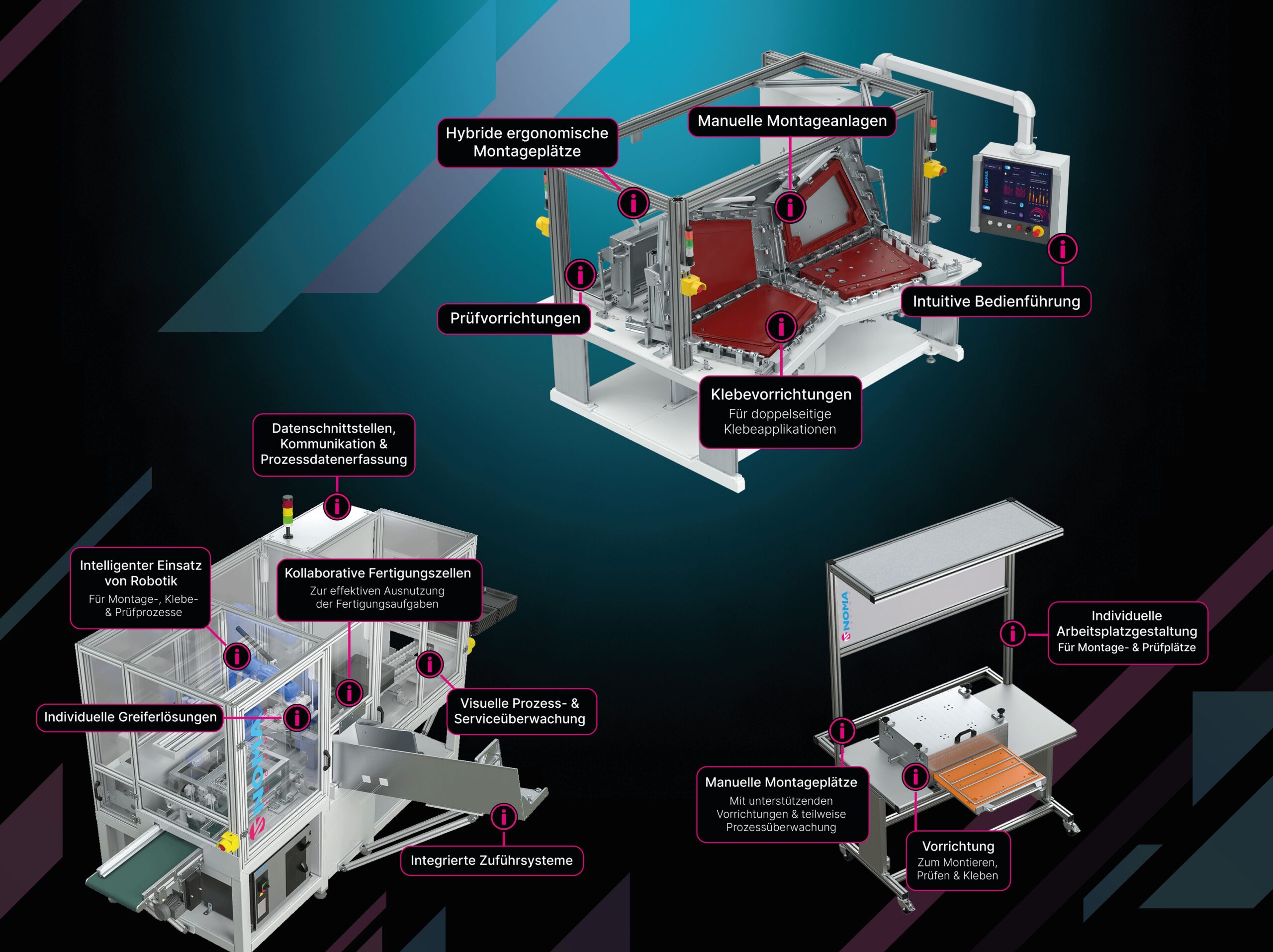

Also this year we would like to invite you to our booth on the MOTEK and Bondexpo in Stuttgart from Oct. 10th– 13th, 2023. Get the latest information on our developments in assembly, testing and bonding automation as well as supporting tooling. Visit us in Hall 5, booth 5422.

More Information: info@noma-gmbh.de

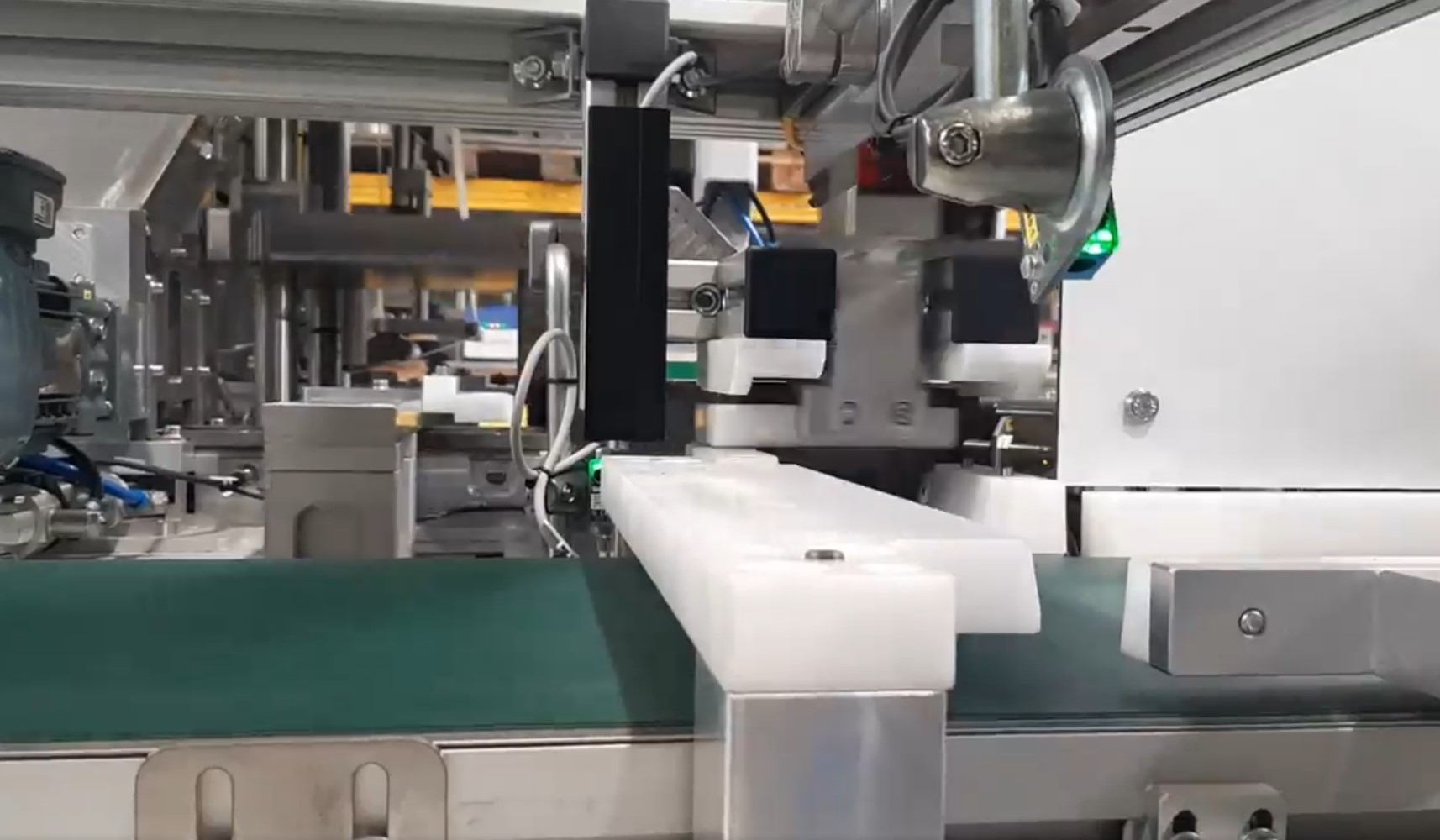

Application example: Forming of steel tubes with different coatings can be realized in the 4 station process lineup of this unit. Different highly tempered mold groups covering a large variety of products and ensure a damage free forming of the final article. In addition, a material bunker enables a max. 6h production without any operator interaction.

More Information: info@noma-gmbh.de

For many of our customers, we are not only a competent contact for special solutions in the areas of automation, assembly systems and devices, but often also a valuable project partner for their own machine concepts. Shown here is an example of a large-format machine frame. With our internal manufacturing capabilities, we cover various areas of machining up to 6x2m component size.

More information: info@noma-gmbh.de

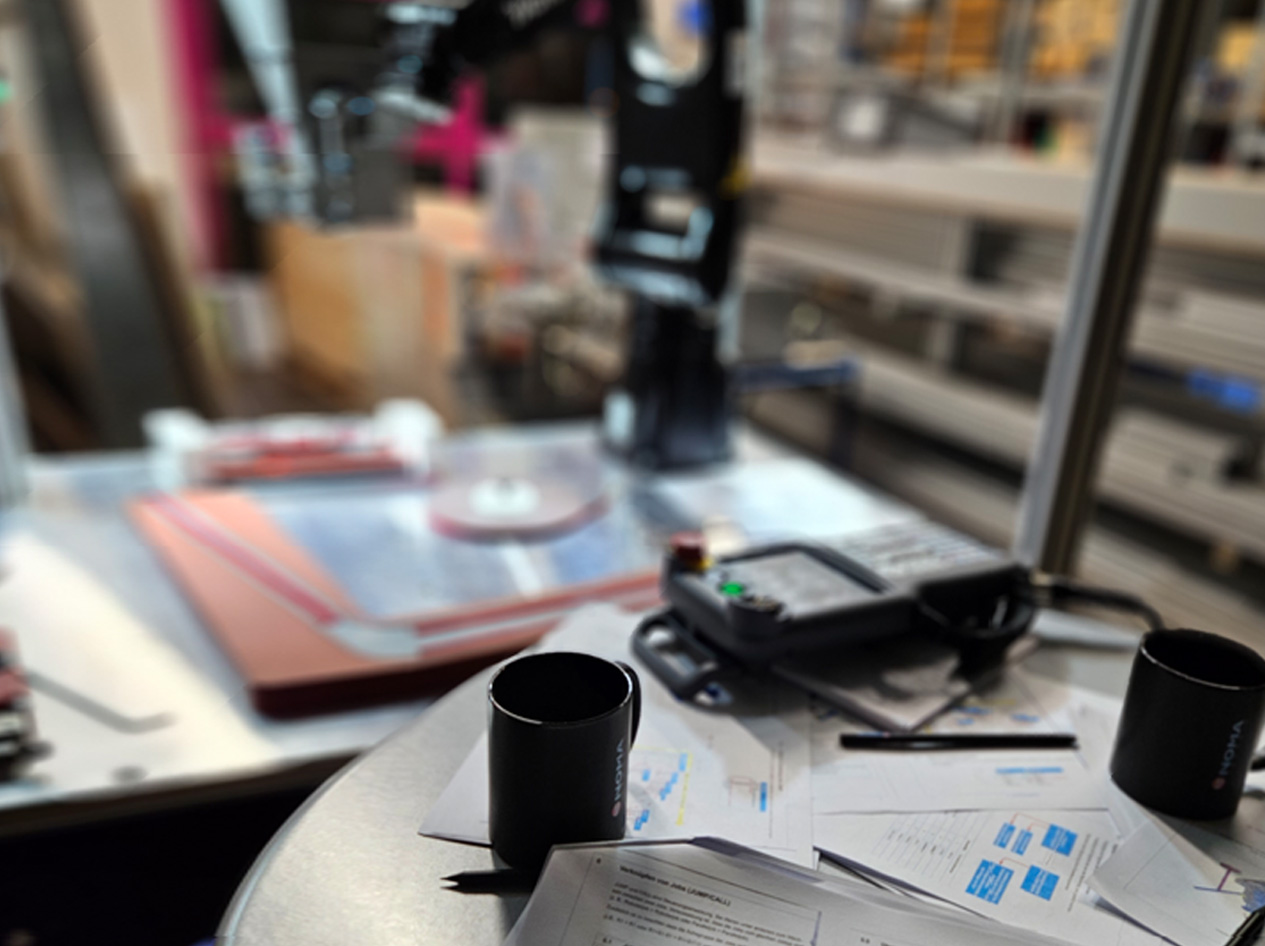

Under the motto of refreshing and expanding knowledge, we completed two training days as a team at our technical center robot cell over the last few days.

New functions and program sequences were programmed and tested live. Thanks also to our training partner for 2 intensive days.

More questions info@noma-gmbh.de

If maximum precision and optimal efficiency are required when applying double-sided adhesive tapes in small batch sizes, Noma Technik provides a proven guidance concept that enables precise positioning in ranges of +/-0.2mm. Link-guided in (almost) any geometry possible because the guide elements can be designed modularly.

Double-sided adhesive tapes can be applied quickly and precisely from the roll.

Questions: info@noma-gmbh.de

After the components have been formed, they must be separated in a further process without the additional intervention of another employee. The frame opening system developed for this purpose is a powerful and compact solution as a self-sufficient unit to the already established processes.

Questions: info@noma-gmbh.de

Application example:

Noma goes through a stringent process ensuring that the manufactured product meets and exceeds the most rigorous of tests before delivery. We analyze the completed product and test its quality and function to ensure the delivery of a system that will boost the performance in assembly, testing or bonding of our customers.

Inquire at: info@noma-gmbh.de

Depending on the process or process requirements, we develop and implement automation concepts with or without robotics. Here is an example of a fully automatic processing of reinforcement brackets.

Feel free to ask below: info@noma-gmbh.de

At this year’s Motek 2022 in Stuttgart, we demonstrated how effectively double-sided adhesive tape can be applied industrially. Here is an example of our applicator VKA 10.1 for industrial adhesive tapes up to 10mm wide.

More information on request at info@noma-gmbh.de.

Technologically, we have almost the entire vertical range of manufacture in-house so that we can consistently manufacture all system components ourselves. Depending on the workload and project status, we can also flexibly integrate our long-standing partners. In particular, we are currently helping our customers to quickly implement projects in the field of electromobility so that their new developments can be consistently scaled up.

Here using the example of a machine frame of a system for the assembly of large-format electric motors! The processing is also carried out in-house with a length of almost 4m.

Feel free to ask info@noma-gmbh.de

Our partner Holzschuh Devich from Hittisau manufactures wooden shoes of unique quality in the 4th generation. In order to join the materials to be processed together, each pair is also processed as a unique piece on the fully automatic gluing system developed by us for this purpose.

More info at: www.holzschuhe.at

….again this year we were able to have many interesting conversations and make new contacts. We were also able to present our solutions in the areas of #automatisierung and #handhabungstechnik – but not only for the adhesive tape processing industry.

Thanks to all visitors!